Main office

Industrijska cesta

6230 Postojna

Slovenia

- Privacy Policy

-

© 2020 PET PAK

All rights reserved.

At PET PAK, we are committed to providing you with packaging solutions of the highest quality.

Packaging which, in addition to following a defined set of technical guidelines, is also uncontaminated, safe to use and made in accordance with a strict set of standards for packaging food, cosmetics and pharmaceuticals.

To make sure that our production process follows good manufacturing practices, we organised and structured our plant in a way that maximises the cleanliness and safety of its interior, as well as exterior.

The plant is built in an area that is far away from any major pollutants.

Offices, production areas and warehouses are placed in a way that minimizes the chance of cross-contamination.

All tools and machines are designed and constructed in a way that enables easy cleaning and minimizes the chance of cross-contamination during production.

Materials used in construction protect the plant from possible contamination.

The plant has separated production areas, material storage, offices, dining areas, locker rooms, lavatories, disinfection stations, glass areas, warehouses and waste collection areas.

Internal areas, as well as external roads, yards and parking lots are continuously cleaned and maintained to ensure optimal safety levels.

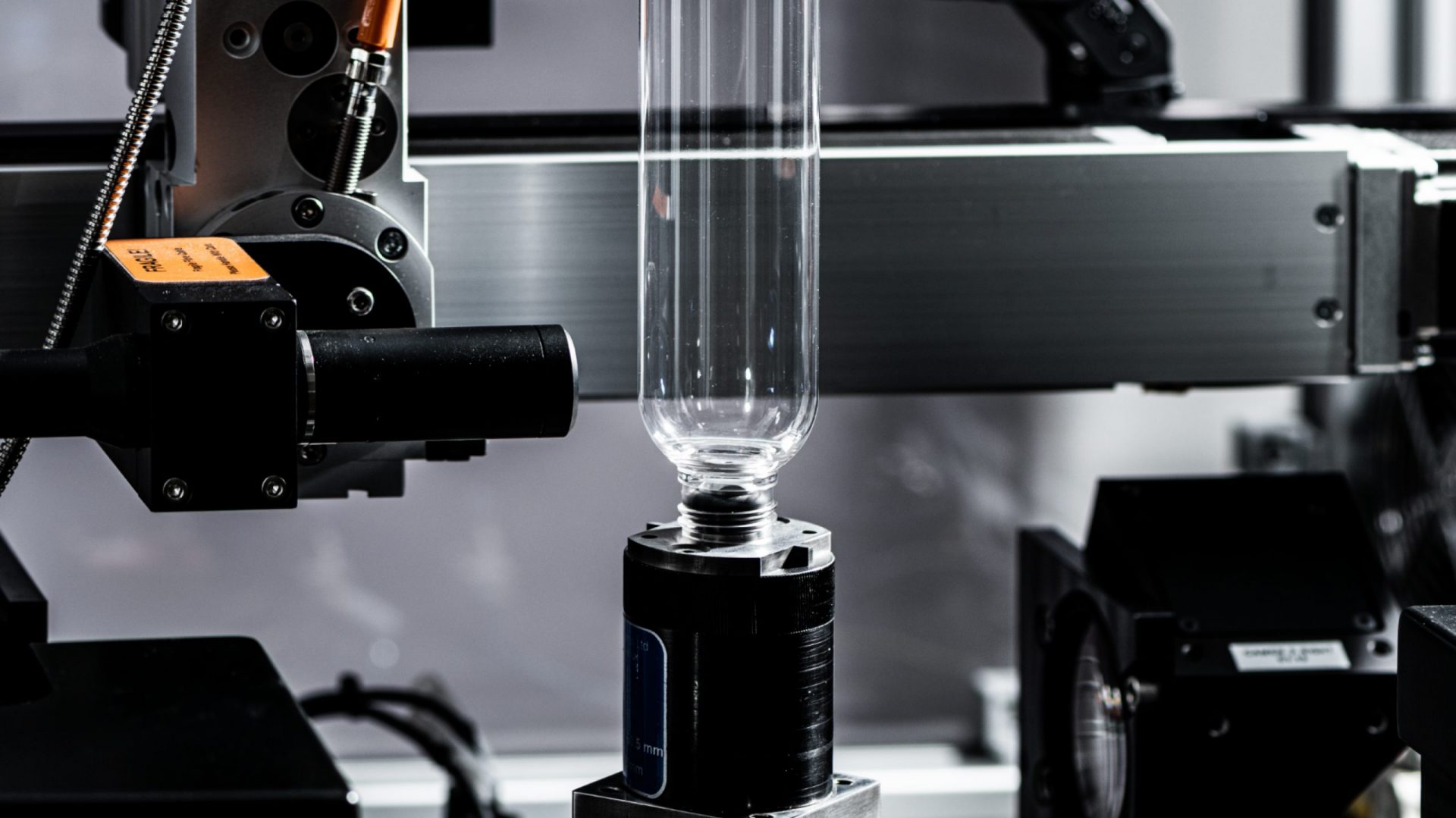

Another aspect that helps us achieve an optimal level of product quality, cleanliness and safety is the machinery we use in our production plant.

Nissei ASB machines for injection stretch blow moulding are not only ideal for creating various types of PET packaging, but they also prevent any possibility of contamination because the entire manufacturing process happens within their closed chambers.

Manufacturing process is followed by high level of automation in all aspects of the company production which ensures that our products can be delivered to the end customer without being thouched by human hand during the whole production process.

To ensure that every bottle, jar and closure that comes off our production lines is created according to set quality standards and the specifications we agreed upon, our Quality Control team conducts a number of automated and manual measurements before, during and after the manufacturing process.

Product height

Product width

Product volume

Product weight

Wall thickness

Neck width

Wall smoothness

Colour accuracy

The entire manufacturing process is done within our plant, and this enables us to manage every aspect of production — from the good manufacturing practices and cleanliness of our production lines, to employee training, choice of raw materials and machine setup.

Every element is set up in a way that ensures the maximum quality of the final packaging, and its safety for your products and customers.

In addition to continuous measurements, we take our packaging through a series of tests to ensure maximum quality across the board.

Visual quality inspection

Production line camera inspection

Daily product measurement

Top-load testing

Fill point and brim-full capacity control

Drop testing

Leakage control

Cap torque measurement

Flip top cap opening and closing

Hinge cap force removal

Tamper evident and CRC cap testing

All our employees undergo continuous training, which is regularly instituted, updated and validated.

Before being used, raw materials we acquire from our suppliers need to pass the inspection from laboratories.

Before starting with large-scale production, we conduct a complete analysis of the first small batch of products to detect any potential flaws.

Once the production process has finished, packaging goes through one final quality inspection before being prepared for delivery.

All external and internal areas and facilities within our production plant are regularly cleaned and maintained.

To ensure that all of our equipment, tools and machines perform optimally, we conduct regular maintenance and calibration.

During the manufacturing process, we conduct thousands of manual and automatic tests and measurements.

Our Quality Control team regularly conducts internal audits of all activities, and addresses any potential irregularities.

Want us to create packaging for your products?